The concept of allocation

Having a look at today’s production planning in manufacturing firms, usually a sales department accepts an order from a customer and passes it on to the production department. As production generally has to deal with limited capacity in terms of machines and manpower as well as with limited raw and pre-processed material, production planning and scheduling algorithms are used to calculate near-to-optimum production plan. This approach called MRP II (Manufacturing Resource Planning) has been used for almost two decades now with only gradual extensions.

|

What planning functions support the inTime negotiation mechanism? |

The inTime approach for capacity and resource allocation is intended to enhance and improve this approach so that it overcomes the purely local and restriction-based view of MRP II that is implemented in today’s ERP systems. Instead, the consequences of local decision making for the partner network will be considered in the production schedule through bilaterally negotiated incentives. This will lead to an improved performance of the overall partner network because positive and negative externalities, currently incurred on the network, will be internalised and thus be part of the objective function of inTime’s modified production scheduling approach.

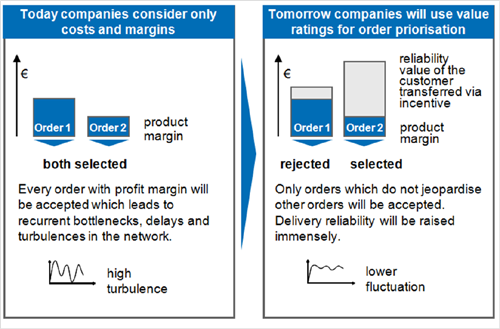

The effect of incentives is two-fold: on the one hand, it is signalling the desired behaviour from the beneficiaries’ point of view. On the other hand, it creates a fair share between costs and benefits resulting from a specific behaviour. Without incentives, the typical decision situation is as such that a customer benefits from an early delivery date, whereas the supplier has to bear the costs for a suboptimal production plan. Incentive-based allocation mechanisms however balance this unfair share of costs and benefits and thus create a win-win situation for both partners, and further for the whole partner network (see Fig. 7).

Fig. 7 – A decrease of turbulence in the network can be realised by monetary incentives for in time delivery

A major research challenge on the allocation level will be the incorporation of the inTime incentive approach into today’s enterprise systems. As production planning and scheduling has been highly automated since the advent of ERP systems, it is essential to integrate our approach directly into these systems. The challenge however is not purely technical. Above all, further research work is necessary to develop modifications for scheduling algorithms as applied in current production planning systems in order to enable these systems to deal with the inTime incentive-based capacity and resource allocation in the same automated way as today.